Products

ABOUT US

Shanghai STD Fluid Machinery Technology Co., Ltd.

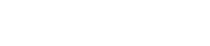

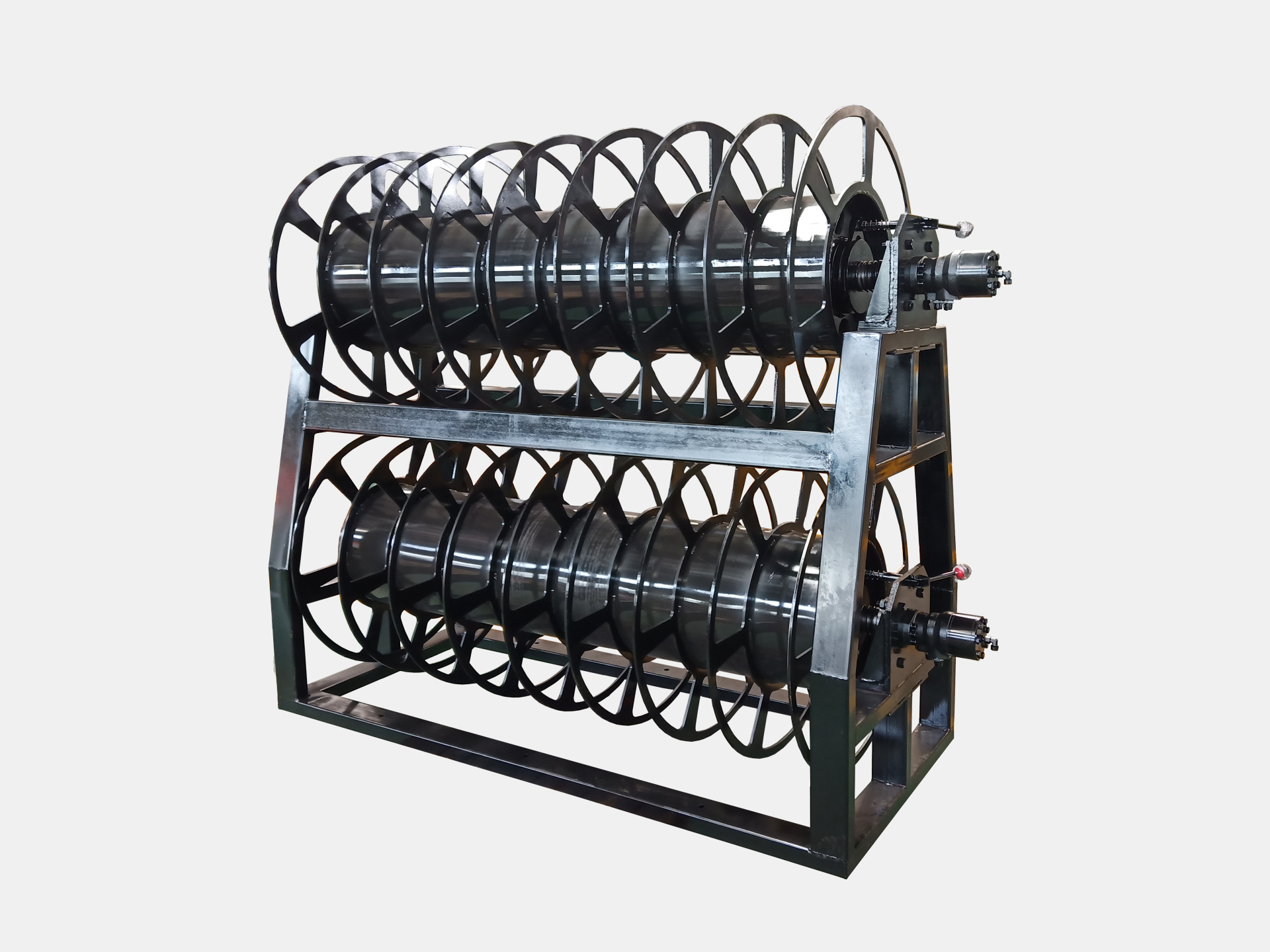

Shanghai STD Fluid Machinery Technology Co., Ltd. was established in 2007 with a registered capital of 5 million. It is located at No. 333 Jinxiang Road, Shanghai Free Trade Zone. There are 65 employees and 9 technicians. Our company mainly has hydraulic cylinders. Hydraulic station, automatic leveling legs, electric leveling legs and other on-board hydraulic and electric systems design and development, and provide hydraulic technology, electro-hydraulic, electric control technology solutions and ...

Read MoreService

Business advantage

News

Unlocking the Power of Hydraulic Cylinder Pistons: What You Need to Know

2025-12-15

Pump Up Your Knowledge: The Ins and Outs of Hydraulic Cylinder Design

2025-12-14

The Mighty Hydraulic Cylinder Jack: Powering Progress in Various Industries

2025-12-14