PRODUCT CENTER

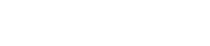

Welding hydraulic cylinder

Category:

Whatsapp:

E-mail:

Product Catalogue

DownloadDescriptions

-

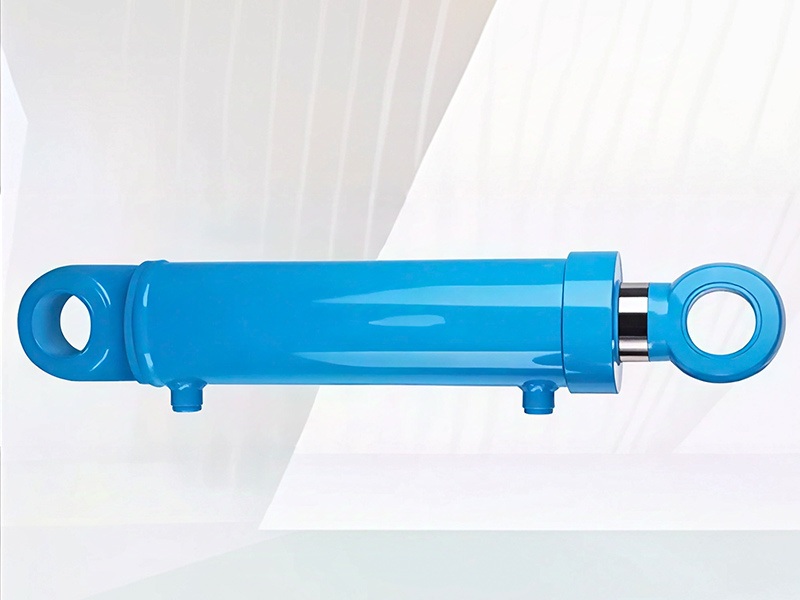

Main components:

1. Cylinder Barrel – Internal roller burnished, surface finish Ra0.4.

2. Piston Rod – Chrome-plated surface, precision ground, finish Ra0.4.

3. Piston and Its Seals

4. Guide Bush and Its Seals

5. Welded Base – Welded connection, long service life.

6. Rod End Clevis – Optional threaded ends (internal or external).

7. Spherical Bearing – Optionally available with self-lubricating bushings or other types.

8. Hydraulic Ports – Customizable upon request.

9. Grease Fitting – Used to inject lubricant into the spherical bearing.

Technical data:

1. Working Pressure:

· Rated working pressure: 16–31.5 MPa (160–315 bar)

· Maximum working pressure: 1.5 × rated pressure

2. Operating Temperature:

· Normal operation: -40°C to +80°C

· Special requirements needed if exceeding this range.

3. Hydraulic Ports:

· Counterbored port connections, sealed with gaskets.

4. Tolerances:

· Spherical bearings & self-lubricating bushings: ISO standard

· Journal tolerance for trunnion pins: f8

5. Hydraulic Fluid:

· Mineral-based oil, contamination level ≤ ISO-DIS 4406 16/13

· Other fluids require special notification.

6. Speed:

· Maximum piston speed: 0.6 m/s

· Higher speeds need special consideration.

7. Stroke Length:

· Maximum: 3000 mm

· For long-stroke cylinders, internal guide bushings may be required to reduce support loads on the piston and rod.

8. Piston Rod:

· Chrome-plated surface

· Materials: 45# steel, 304 stainless steel, 316 stainless steel

Welding hydraulic cylinder

Category:

Whatsapp:

E-mail:

Descriptions

-

Main components:

1. Cylinder Barrel – Internal roller burnished, surface finish Ra0.4.

2. Piston Rod – Chrome-plated surface, precision ground, finish Ra0.4.

3. Piston and Its Seals

4. Guide Bush and Its Seals

5. Welded Base – Welded connection, long service life.

6. Rod End Clevis – Optional threaded ends (internal or external).

7. Spherical Bearing – Optionally available with self-lubricating bushings or other types.

8. Hydraulic Ports – Customizable upon request.

9. Grease Fitting – Used to inject lubricant into the spherical bearing.

Technical data:

1. Working Pressure:

· Rated working pressure: 16–31.5 MPa (160–315 bar)

· Maximum working pressure: 1.5 × rated pressure

2. Operating Temperature:

· Normal operation: -40°C to +80°C

· Special requirements needed if exceeding this range.

3. Hydraulic Ports:

· Counterbored port connections, sealed with gaskets.

4. Tolerances:

· Spherical bearings & self-lubricating bushings: ISO standard

· Journal tolerance for trunnion pins: f8

5. Hydraulic Fluid:

· Mineral-based oil, contamination level ≤ ISO-DIS 4406 16/13

· Other fluids require special notification.

6. Speed:

· Maximum piston speed: 0.6 m/s

· Higher speeds need special consideration.

7. Stroke Length:

· Maximum: 3000 mm

· For long-stroke cylinders, internal guide bushings may be required to reduce support loads on the piston and rod.

8. Piston Rod:

· Chrome-plated surface

· Materials: 45# steel, 304 stainless steel, 316 stainless steel

Keyword:

Welding hydraulic cylinder

hydraulic cylinder

Previous:

Inquiry

Related Products

More >>